Surface Treatment

Thorough and effective surface treatment

East Metal finishes the pieces with the surface treatment(s) that are best suited to the job. This applies to surface blasting as well as metallisation, galvanisation and painting.

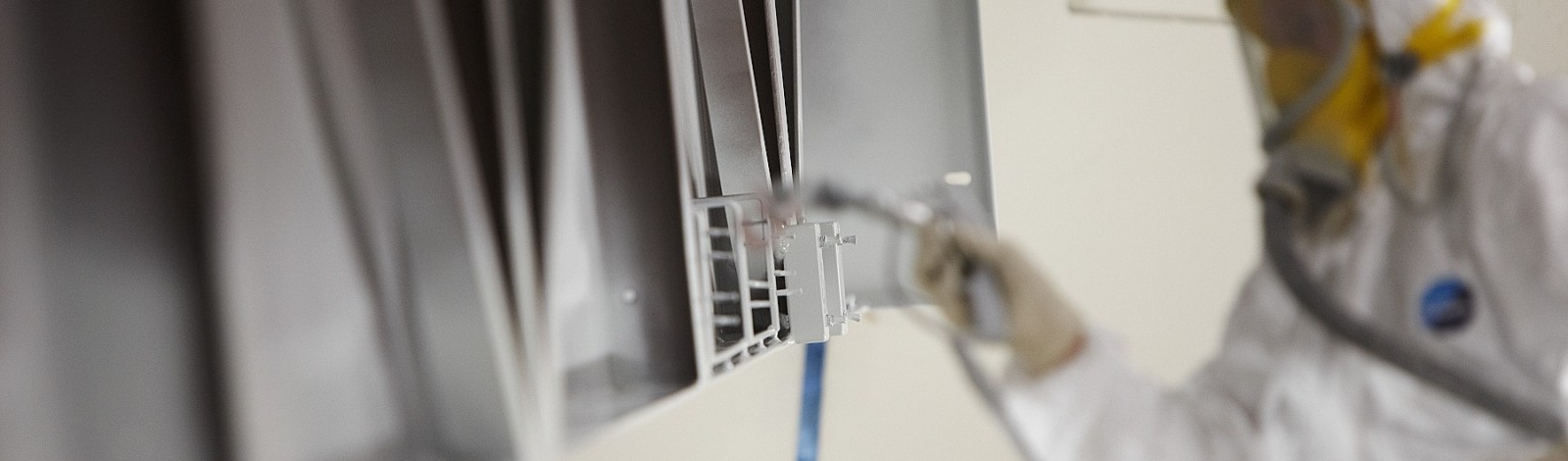

Surface blasting

Traditionally, the iron and steel industries have used sand blasting before metallisation and galvanisation. At East Metal, we surface blast the piece with metal shot. This surface blasting is a far more favourable method, as we avoid the risk of small fragments of sand boring into the steel and subsequently destroying the metal from within.

Galvanisation and metallisation

Regardless of the technology, our processes and regular quality controls ensure that we comply with the strictest requirements in the industry, in accordance with DS/EN ISO 1461.

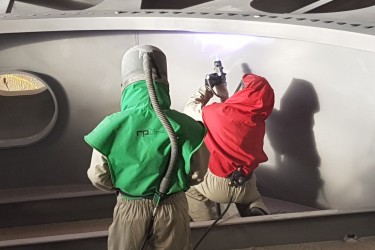

Surface Treatment in class C5

We work at a high level of quality in all sub-processes around surface treatment. The painting department handles jobs right up to corrosion category C5-M, which provides the finished product with an extremely high level of protection against corrosion.

Best possible result

This means that we always choose the method or methods that ensure the best possible result in relation to the customer's requirements and the specific task. We complete most processes at our own factory facilities, while others are outsourced to regular and quality conscious collaborative partners in either Latvia or Western Europe.